Innovative approach to move up biomass value chain

By Karamjit Singh September 3, 2013

- Agensi Inovasi Malaysia promotes a new model for plantations

- Public policy change in South Korea offers immediate opportunity

THE National Biomass Strategy 2020 (NBS) introduced in 2010 puts the spotlight on the readily available raw material in Malaysia and highlights opportunities to convert this into higher value output beyond its current use as fertiliser, and instead for wood products and as a source of energy.

THE National Biomass Strategy 2020 (NBS) introduced in 2010 puts the spotlight on the readily available raw material in Malaysia and highlights opportunities to convert this into higher value output beyond its current use as fertiliser, and instead for wood products and as a source of energy.

Examples of higher value products would be pellets used for energy, biofuels and bio-based chemicals.

The NBS estimates these efforts can potentially translate into an incremental RM30 billion (US$9 billion) in Gross National Income and an additional 66,000 new jobs by 2020.

Biomass is the term used to describe waste from organic material that can be converted to energy. But Malaysia, through efforts being promoted by Agensi Inovasi Malaysia (AIM) or the Malaysian Innovation Agency, is looking at the long term beyond energy, and to biofuels and biochemicals.

While the technology challenge of converting biomass into these higher value products is still significant, as is typical of how technology works, significant progress is being made to allow for the conversion of biomass into these higher value segments.

It is now estimated that biofuels from lignocellulosic (e.g. forest and agricultural residues) biomass are expected to reach commercial scale around 2015, with bio-based chemicals between 2015 and 2020. The term lignocellulosic biomass refers to the main building blocks of plant matter: Lignin, cellulose and hemicellulose.

What is interesting here is that AIM has been promoting the idea of Malaysian biomass owners, especially the oil palm plantations, to use their biomass to participate as partners instead of merely being low cost suppliers to the downsteam players in the biofuel and biochemical markets.

Downstream players will bring the technology, the market access and the supply chain to the table, while their Malaysian partners will bring the all-important raw material.

The message is, “By all means come to Malaysia but work together with the locals as partners to ensure your supply of raw material and do not take them as a low cost source of feedstock supply,” says Bas Melssen, AIM executive vice-president.

It is a novel approach and will take time to convince sceptical Malaysian oil palm plantations of the economic value of this approach which forsakes short-term profit for long-term gain.

“That is the tricky part,” says Melssen, who as the national biomass strategy team leader, is AIM’s point man in this process of educating the market and convincing sceptical players. But he sees hope and signs of progress.

Melssen has regularly met industry players including visiting their plantations. He recently witnessed a breakthrough in the unlikely town of Lahad Datu, which has been in the news after an incursion by Filipino terrorists.

Lahad Datu is home to a cluster of 90, mainly independent, oil palm mills. More importantly, these mills are densely located within a 100km radius of each other. This high density means that transportation costs are low.

“That’s very important because even if you had 40 mills of your own, if they were located far from each other, that scale gives you no advantage. In fact, the cost to transport palm oil biomass to a processing mill will kill you if it is located far away,” warns Melssen.

Because of the economic feasibility of the cluster of mills and plantations at Lahad Datu, AIM approached the Sabah state government and the Palm Oil Industrial Cluster (POIC) about its plan to have local players partner with foreign players.

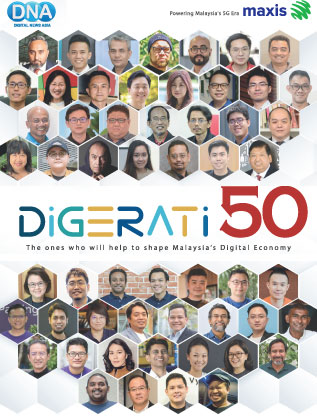

“Both AIM and the state government saw this as a real opportunity for the industry to keep the value here instead of shipping their biomass out as a commodity,” says Melssen (pic).

“Both AIM and the state government saw this as a real opportunity for the industry to keep the value here instead of shipping their biomass out as a commodity,” says Melssen (pic).

So they started talking with the private mill owners and plantations. Most of them, as expected, were using their biomass as fertiliser and burning it for energy. But AIM and the state government started engaging them and pointing out the potential of being involved in higher value downstream activities.

“The only problem was that to enjoy the higher value activities, they needed scale and this meant they had to team up with their neighbours – people they historically competed against.

“But we got 25 of them into a room and pointed all this out to them. This made them realise the value of becoming partners with each other investing their biomass resources together,” says Melssen, describing the mood as “dynamic in a very interesting way.”

Fortunately, developments in South Korea have presented an incentive for the players to work together for mutual benefit over the mid-term.

The Korean Government has mandated that by 2020, its power plants generate 10% of their energy from renewable sources or face a fine. As a result, the country needs four million tonnes of pallets a year by 2020.

The only way the owners could benefit from this is to partner with each other. They have created teams of between five and seven to establish joint ventures to work on this, and build a commercial scale pallet plant.

With three- to five-year contracts the norm in this niche, and with US$180 per tonne of pellets, the payback period ranges from three to five years.

Surprisingly, this is not AIM’s game plan because the players in Lahad Datu are just exporting pellets.

“It is not really what we want in the long term but is a great stepping stone to get involved in the biomass industry and for its players to start mobilising for the longer term future we see,” says Melssen.

Bio-based ethanol looms big in this future. What AIM and Sabah POIC are saying is that the owners need around 30 mills under their hands to be able to do anything meaningful. It is not about selling their palm oil biomass, but rather, offering it in return for a stake in the downstream business.

Will the downstream players who own the technology for processing biomass into the higher value products be receptive to the idea of actually partnering with their suppliers instead of relying on them to be the low cost provider for their raw material?

Melssen insists that the signs are very promising. The next few months should shed more light on this innovative approach.

Related Stories:

Things are moving, says AIM

Bioeconomy to focus on renewable resources

10 biotech EPPs launched

For more technology news and the latest updates, follow @dnewsasia on Twitter or Like us on Facebook.