Astrata aims to boost supply chain solutions during coronavirus pandemic

By Edwin Yapp May 28, 2020

- Pushes ‘anti fragile systems’ as a way to holistically track supply chain

- Targeting Malaysian government and enterprises with complex systems

THERE is no doubt that the coronavirus pandemic has brought disruption to the way business is done in the world today. But as difficult as the coronavirus impact is to a wide range of verticals, one sector that is particularly sensitive to sharp changes is the supply chain and logistics business, argues the chief executive of Astrata Group.

Speaking to Digital News Asia in an exclusive interview, its chairman and chief executive officer George Kappaz notes that while the coronavirus crisis has indeed exacerbated bottlenecks in the supply chain and logistics industry, the situation only serves to further expose how weak some companies’ supply chains are.

“Globally, we see a difficult recovery ahead, as the demand in the supply chain has grown exponentially,” he says. “But the coronavirus pandemic has only painfully highlighted how weak the supply chain system is [to begin with], especially for enterprises that have not deployed the latest supply chain and asset optimisation tools.”

Jointly headquartered in Singapore and New York, the Astrata Group is an enterprise management software and advanced location-based IT solutions provider with more than 20 years experience with major operations and offices in Europe, US and Asia-Pacific.

Kappaz, who splits his time between New York and Singapore, says when the pandemic is eventually brought under control, enterprises mustn’t be naïve to think that something similar will not happen again. In a globalised world, the next disruption is just around the corner so it’s imperative that businesses do not rest on their laurels, he warns.

Elaborating on some of the challenges facing enterprises’ supply chains today, Kappaz points out that many of them aren’t automated and optimised, and as a result, companies become less resilient to sudden shocks and supply shortages.

“There is a lack of actionable data in the supply chain so companies are unable to identify and connect with alternative solutions when there are sudden and rapid changes to the supply chain.

“Today, most companies still make manual changes to journey and delivery management, and this causes a variety of burdensome duties across different departments.

“On top of that, businesses have poor awareness of what’s happening across their entire end-to-end supply chain. And there is no way to manage multiple data points and get something sensible out of it,” he claims.

‘Anti fragile systems’

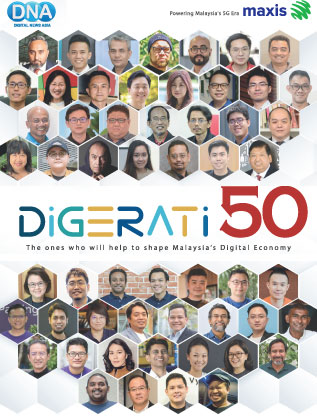

According to Kappaz (pic, above), one effective way to deal with these challenges is to adopt what he calls a ‘digital anti fragile’ supply chain solution.

Essentially, a digital anti fragile system is a solution that is able to digitally monitor, record and process and optimise data across the entire end-to-end supply chain.

Kappaz claims such solutions can help companies thrive in a crisis rather than crumble because all parties can benefit from increased access to data.

“Decision makers can spot single points of failure and make informed choices about how to manage any disruption,” he explains. “The enhanced ability to collaborate with sellers and other parties in the supply chain ecosystem means these decisions can be implemented quickly and reliably, which is critical in times of stress.”

At the heart of a digital anti fragile system is supply chain and asset optimisation and automation technology.

“Astrata has been in the business of enterprise operational software, fleet management technologies and advanced telematics for a long time,” he says.

“Over the years, we have enhanced our solutions from traditional track and trace towards safety, big data, analytics, supply chain visibility and open telematics,” he says.

Asked what industries would benefit from such a proposition, Kappaz says Astrata’s solutions meet the needs of enterprises who have complex supply chains.

“For example, we serve those who need to digitalise and optimise their supply chains, and this includes anyone who needs to know where their drivers or assets are; anyone who has multiple devices installed in their vehicles; and anyone with no visibility of how to crisis manage their ecosystem.”

Apart from this, Kappaz says Astrata also serves those who lack flexibility in managing goods, transport, finances, as well as those who need flexible workflow and transportation management systems.

Finally, it also serves those who need to protect their employees from exposure such as monitoring and geofencing their routes to ensure safety and driving behavior.

Quizzed as to how Astrata’s solution differs from competitors in the market, Kappaz claims to have the most comprehensive range of solutions for the widest range of industry verticals – seven in total.

“On top of that, we are very flexible. Although we have our own hardware platform, we are not attached to them, and our customers just need to connect their platforms to us via software.

“We also have the capabilities to extract, analyse and enrich data regardless of the source,” he explains. “We are hardware agnostic, fully software- and cloud-based. Also, we are modular and can deploy immediately.”

Asked what are its plans for Malaysia, given that Astrata is based in neighbouring Singapore, Kappaz says Astrata has been a trusted provider of the Singapore government for years and the lessons learnt from that has allowed them to understand and respond quickly to the acute and long-term needs resulting from the coronavirus crisis.

“We see opportunities to help governments and essential public service providers, especially when movement is restricted and evidence of health and safety is required,” he explains. “This is where we believe Astrata can help. Kappaz also says that during these times, supply chain providers and online retail companies will need to enable automation to alleviate bottlenecks, provide visibility of their fleets and goods.

“Southeast Asia, Singapore and Malaysia have always been, and will continue to be very, very important markets for us,” he stresses. “As more companies in various sectors look to technology to improve operations and profitability, as well as scalability, we will be right there with them.”

Related Stories :